Our Goal

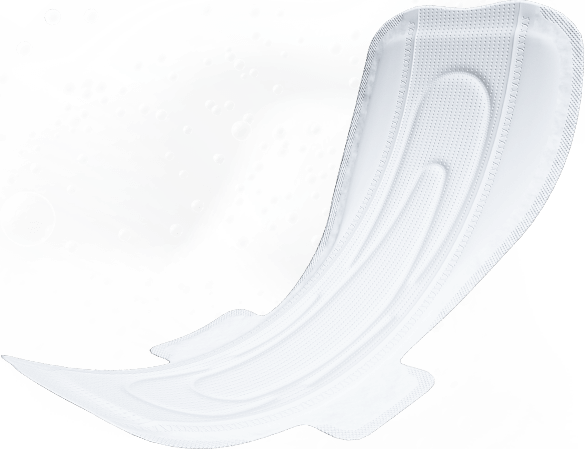

Strict Medical-Grade Standards for Double Protection

To meet safety and hygiene requirements, we select high-quality raw materials that undergo thorough screening and testing to ensure they contain no harmful substances. Production follows strict medical-grade standards, with each process carefully controlled and certified.

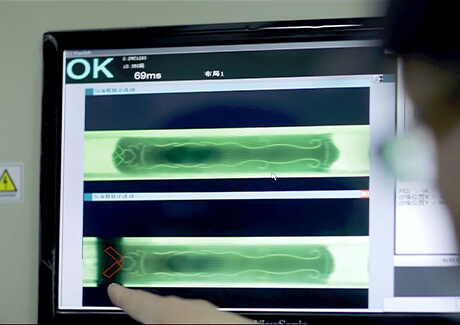

Equipped with industry-leading high-speed production lines and automated equipment, we ensure the consistency and stability of our products.

We always adhere to strict standards.

We select only high-quality raw materials, with rigorous checks at every stage—from incoming raw material inspection to finished product quality testing—to ensure compliance with high standards. We also have a professional quality control team responsible for overseeing and managing each step of the production process.

High Standards, Strict Requirements: This is our approach to product quality.

We select only high-quality raw materials, with rigorous checks at every stage—from incoming raw material inspection to finished product quality testing—to ensure compliance with high standards. We also have a professional quality control team responsible for overseeing and managing each step of the production process.

Our Ingredient Safety Requirements

To address this, we have established strict safety limits for our products. Hygiene and safety indicators are verified by third-party testing reports, and each batch includes an internal report for microbiological indicators.